Our testing capabilities

At SolutionAir the foundation of product development is science validated through rigorous testing.

Psychrometric Chamber

SolutionAir has built a state of the art psychrometric lab to test heating and cooling for rooftop units and several complementary mechanical products:

- Precise performance and longevity testing on custom rooftop units with packaged DX up to 20 tons.

- Testing cooling coil and heating coil capacity in accordance with AHRI 440 and AHRI 410.

- Room conditioning equipment capable of conditioning to a wide range of temperature and humidity set-points.

- Water supply has an expanded range of temperature, flow and pressure capable of exceeding any of our products fluid supply requirements.

RESEARCH & DEVELOPMENT

Innovative technology and unparalleled testing capability have attracted clients from across North America.

If you would like to tour our lab contact us today to arrange a visit.

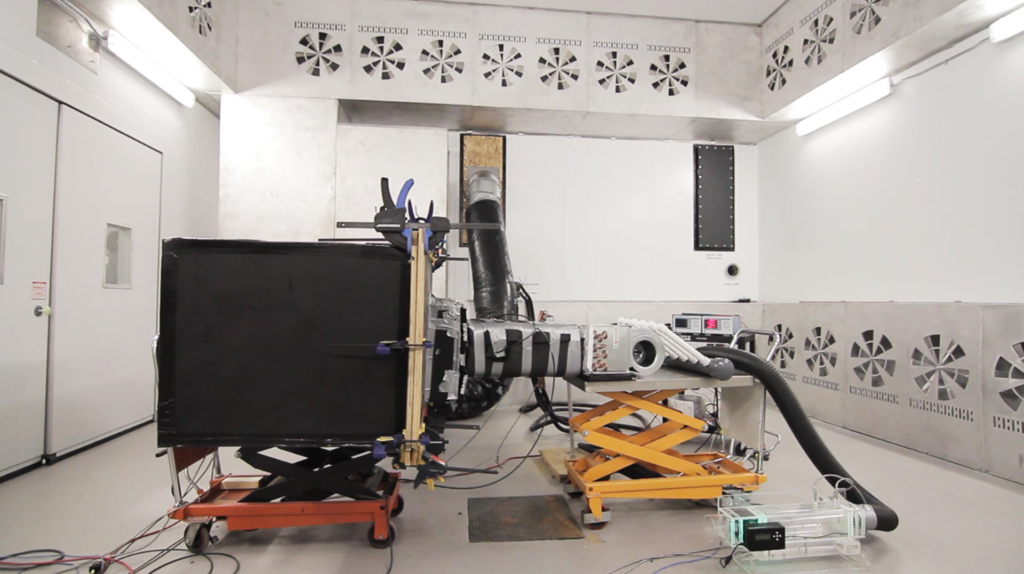

Environmental Chamber

The SolutionAir Environmental Chamber is capable of testing products to meet ASHRAE Standard 84, CSA C439, ISO 16494 & AHRI 1060, while maintaining temperatures ranging from -40°C to +40°C (-40°F to 104°F).

The chamber, along with the custom designed cooling system, is paired with a SolutionAir custom air handling unit to simulate building return air.

- Two SolutionAir nozzle banks meet ASHRAE 41.2 to accurately measure both supply and return airflows.

- NIST certified temperature and humidity sensors are strategically positioned to ensure all variables are captured and logged.

Gas Testing Laboratory

A CSA certified Gas Laboratory allows SolutionAir to conduct product testing and safety certification in-house without the need for CSA personnel to be on site, resulting in:

- Faster product development cycle

- Testing and certification of new products

High quality results for customer demonstrations, customized units & control testing, training and site issue analysis